The goal of supply chain risk management (SCRM) is to minimize any disruption and keep the flow of goods moving. But with the increasing complexity of global supply chains – including multiple tiers and shared industry suppliers among competitors – human-based risk management methods can no longer do the job on their own. That’s where artificial intelligence (AI)comes in.

Transportation and logistics, a crucial part of the supply chain, has been cited by Price Waterhouse Coopers as the fourth most-impacted industry when it comes to AI. Why transportation and logistics? Artificial intelligence collects and analyzes massive amounts of data from different data sources, giving transportation and logistics leaders insights they never had in the past. It has opened up capabilities across the industry, from optimizing routes and automating trucks to predicting transit times and avoiding weather events.

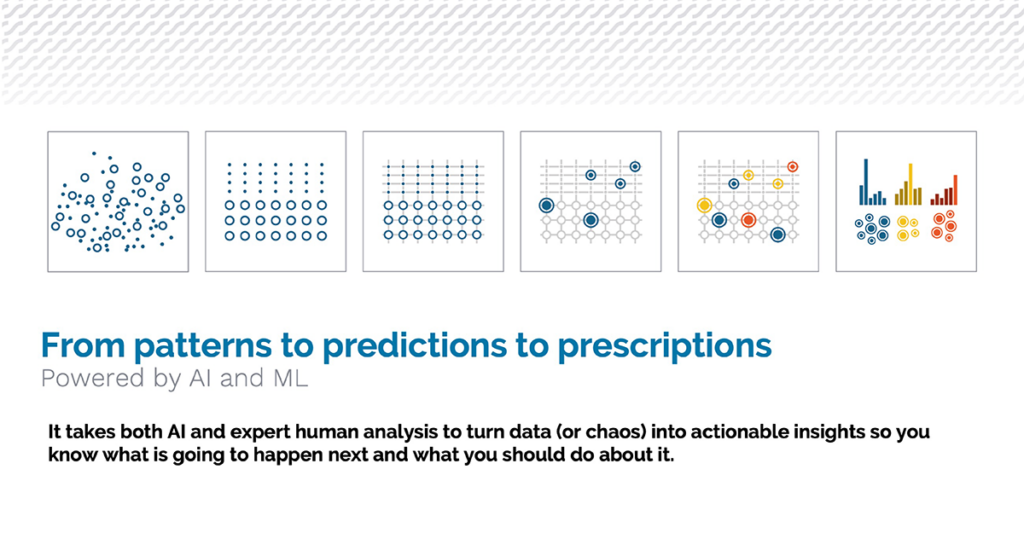

AI can identify patterns and correlations in data, then get smarter via personalized input. Supply chain managers and executives can get a real-time view of risks across the entire supply network and make more informed decisions about how to mitigate them.

LEARN MORE ABOUT HOW SUPPLY CHAIN RISK MANAGEMENT WORKS: FREE DOWNLOAD

Here, we explore how AI is the keystone of today’s supply chain risk management, where human input is critical, and the cost benefits it can offer. If you’re responsible for managing a supply chain, you’ll learn how AI can help you reduce risk and keep your operation running smoothly.

What is artificial intelligence in logistics?

Gartner defines AI as technology that applies advanced analysis and logic-based techniques, including machine learning, to interpret events, support and automate decisions, and take actions. It also says AI can be broken down into two categories: either used to augment human capabilities and reduce errors, or it used to automate key processes. When it comes to transportation and logistics, both use cases apply.

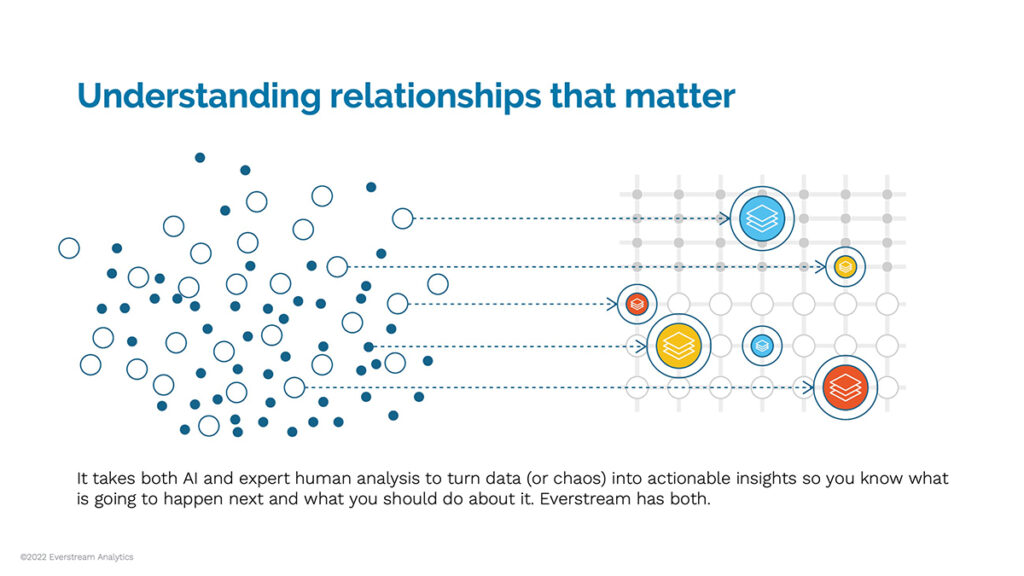

Logistics leaders often lack the tools they need to identify, assess, and mitigate risks, usually because they do not have access to all the data they need to move accurately and rapidly. The tools they do have are disconnected and fail to provide a comprehensive view of their risks, the probability, and severity of those risks, and exactly where, when, and how those risks could impact individual shipments. Legacy systems and manual processes collect and crunch numbers from disjointed systems, all of which takes time, introduces the risk for error, and results in an incomplete view of what matters most.

How artificial intelligence is used in supply chain risk management

AI is the ability of a computer to learn and make increasingly more appropriate decisions without the direct intervention or programming of a human each time. When applied to supply chain risk management, artificial intelligence algorithms can identify patterns and trends that are otherwise difficult to spot, then incorporate personalized guidelines and feedback, and immediately adjust plans to mitigate any potential risks identified.

Risk is inherent in the supply chain but with AI, companies have real-time data to anticipate risk before those risks turn into issues. Leaders can make data-backed decisions early in the shipping process when mitigation efforts have the greatest chance for success.

The key to fully optimizing AI in the supply chain is to use it to forecast and make predictions. Predictive analytics is an important aspect of this advanced and intelligent technology, giving leaders a way to go a step beyond the identification and assessment of risks to predict what could happen based on reliable data.

To respond quickly to identified risks, which is the most important aspect of mitigation efforts, leaders need their decisions to be more automated. As Gartner has said, automating processes, including the decision-making process, is where AI shines. Predictive analytics and machine learning are powerful tools that when combined, deliver unprecedented capabilities at scale.

Ongoing AI management provides insights that help human users monitor their entire supply chain, from top to bottom, with accuracy and precision. AI can provide end-to-end visibility from procurement to logistics, alerting supply chain managers to potential proactive actions before there’s a disruption. It can even rank and score each risk according to a company’s standards.

Automated AI monitoring reduces costs throughout the entire supply network by identifying inefficiencies and continually improving them based on what it has learned.

For example, AI can help businesses make more informed decisions about their inventory levels and pricing strategies. AI analysis can identify potential threats within the supply chain by analyzing data from suppliers or customers to detect any irregularities or changes – like noting anomalies in supplier payments or delivery times.

Track supplier performance over time by monitoring production capabilities, service quality, and cost effectiveness. These insights can help businesses identify new potential suppliers or renegotiate existing contracts with current suppliers. In addition, businesses can use AI tools to analyze customer feedback from previous orders to predict future customer demand or suggest improvements that could help increase sales.

But the biggest advantage of AI monitoring is the computer’s ability to map and monitor an entire supply network, down to the last tier. Instead of waiting for disruption to filter its way up to your operation, AI alerts supply chain managers to risk far down the supply chain, providing valuable days and weeks to shift plans before resources become more expensive or unavailable.

Moving from reactive to proactive

Actionable, predictive intelligence uses machine learning techniques to make risks more predictable, even risks as seemingly unpredictable as the weather and environmental conditions and natural disasters, such as floods, extreme temperatures, and severe storms. Wildfires, social unrest, infrastructure outages, and other risks are all included in the risk assessment. This intelligence also helps with decisioning.

Tools now exist that automate the task of finding lower-risk alternatives to current shipment plans. The technology automatically scans shipments up to three days before and three days after a planned pickup date to compare risk levels. Companies can define their own risk tolerance and set up alerts that notify them when a risk threshold could be met. AI also recommends the lowest-cost equipment options that maintain freight integrity, as well as which mode of transportation and lane are most likely to result in shipments being on time.

It isn’t just real-time data that is important for decision-makers. AI in supply chain management provides historical context so that leaders can identify trends and use those to inform decisions and hone their processes so that they are always learning and improving. The better and faster they become at identifying, assessing, and mitigating risks, the more bite they can make into market share.

These predictive analytics shine a light into potential future events and recommended actions. With past, present, and future perspective, leaders are more aware than ever of their entire ecosystem and able to make decisions with greater confidence, understanding context, dependencies, and scenarios. They can use this data to justify their decisions within the company and externally with customers, setting appropriate delivery expectations, and keeping lines of communication open.

The value of human oversight in artificial intelligence monitoring

By combining human oversight with advanced AI technology, companies can gain insight into potential risks within their supply chains while also gaining greater control over their operations. Human oversight and verification ensure accuracy, precision, and personalization in AI operations.

Human researchers and fact-checkers review and validate the datasets that AI systems use, ensuring that all data points are accurate, relevant, and up to date. Additionally, human review of AI-generated outputs can help to eliminate errors due to misinterpretation or illogical assumptions made by the system. Human experts monitor a system’s performance over time to ensure its accuracy remains consistent as changes occur within the business environment.

Humans are also able to detect patterns or anomalies that may not be immediately apparent to an AI system, allowing for a more comprehensive analysis of potential risks. AI systems may struggle with nuanced, complex scenarios that require a deeper contextual understanding, and human analysts are better suited for detecting subtle relationships between different pieces of information.

On the other hand, human bias must also be taken into consideration when it comes to data review and interpretation. Human reviewers may come from different backgrounds with varying levels of experience. The best supply chain risk monitoring platforms minimize human bias by using protocols and training which promote impartial decision-making, and develop technical safeguards against biased outcomes based on gender, race, or ethnicity.

How artificial intelligence reduces supply chain disruption costs

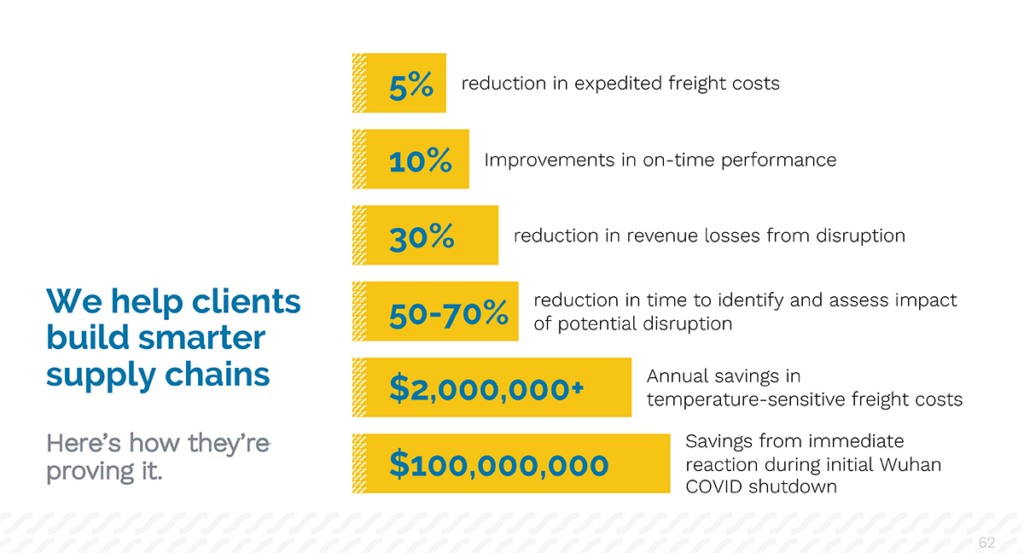

At Everstream Analytics, we apply our AI algorithms and expert analyst oversight to support the world’s largest supply chains. Our clients have seen significant savings after deploying our risk management platform:

- 5% reduction in expedited freight costs

- 10% improvements in on-time performance

- 30% reduction in revenue losses from disruption

- 50-70% reduction in time to identify and assess disruption impact

- $2+ million annual savings in temperature-sensitive freight costs

AI-supported risk management helps reduce costs primarily by scoring risk by how likely it is to happen, and buying companies more time to adjust operations before disruption hits. For example, organizations can notably reduce unexpected delays and reduce costs while also improving customer service. The use of AI also minimizes manual labor efforts, reduces errors, minimizes data inconsistency, and accelerates communication within the organization making it easier to reduce lead time and delivery costs.

Essentially, AI-driven solutions enable organizations to shorten their supply chain risk management cycle times and increase their ROI via improved process visibility, real-time decision making, automated approval controls and much more. Companies can recognize risks faster and are able to take preventive action earlier than ever before. They can also scenario-plan to anticipate likely outcomes.

For today’s supply chains, artificial intelligence is a powerful risk management tool. If you’re ready to learn more, download our special report with a cost-benefit analysis and real-life case studies.

How to bring artificial intelligence into your supply chain

If you are considering an investment into artificial intelligence for your supply chain, your decision will come down to buying an AI risk-management application from a vendor or building it in-house. Supply Chain Dive points out that, “Bringing the required talent on board can be a struggle. Fifty-six percent of respondents considered hiring a top challenge in the current environment and 78% said there was high competition for the talent available.”

Instead, you can focus your budget on software purposely built for logistics leaders who want to make risk more predictable, actionable, and manageable. With comprehensive risk identification and analysis, dynamic planning, and automated decisioning, all of which utilize AI, leaders can have greater confidence they can deliver more loads on time and in full.

For today’s supply chains, artificial intelligence is a powerful risk management tool. If you’re ready to learn more, download our special report with a cost-benefit analysis and real-life case studies.

LEARN MORE ABOUT HOW SUPPLY CHAIN RISK MANAGEMENT WORKS: FREE DOWNLOAD