On-time, in-full – or OTIF as it is commonly referred to – was borne of the concept that retail stores need to be able to better manage their supply chain and manage inventories. By putting suppliers’ and shippers’ feet to the fire by imposing a chargeback fee for late shipments, retailers can be more responsive to customer demand by ensuring the right products in the right volume are on the shelves at the right time.

Walmart may have created the OTIF delivery requirement, but many other big box stores have followed suit, seeing the value in having greater predictability and control over inventories. And it’s easier than ever to incur late shipment fees when companies like Walmart have increased their successful OTIF thresholds to 98%, leaving very little margin for error.

The intention makes financial sense for retailers. However, many supply chain participants aren’t entirely sure how to go about OTIF calculations, or what it may mean for their operations.

What is OTIF in supply chains?

OTIF calculations are intended to measure how well a supplier can deliver on its timeframe commitment, how complete and accurate the order is, and the integrity of the products ordered. Retailers can impose fines on suppliers for poor OTIF performance and evaluate suppliers by their score, motivating suppliers to prioritize those processes that minimize their risk of missing OTIF commitments.

The problem with OTIF calculations, however, is that there is no standard definition for what exactly OTIF means. According to McKinsey, every supply chain stakeholder may have their own interpretation: “Does ‘on-time’ mean on the date requested by the retailer, or the date promised by the manufacturer? Does it mean within the specific delivery slot allocated to the shipment, or any time inside a broader, agreed-upon time window? Should ‘in-full’ be measured at the level of complete orders, line-items, or individual cases?” There is a lot to consider in terms of each retailer’s needs.

For example, items arriving earlier than expected may not be a win for retailers, as they will require storage space and planning. Items arriving late mean empty shelves and frustrated customers who can be all too quick to post negative reviews or shift their loyalties to another brand. Damaged products can’t be sold and must be re-ordered. OTIF requires fitting into the very specific supply chain schedule set by the retailer, developed according to their preferences.

Without a standard definition and expectations, it is difficult to perform accurate OTIF calculations. A McKinsey and Trading Partner Alliance (TPA) survey of 24 major U.S.-based retailers and manufacturers of consumer-packaged goods found that 92% of respondents would prefer an industry standard for OTIF as it would reduce confusion and foster greater partner collaboration, all of which would likely help them keep the supply chain operating more efficiently and effectively.

With a common definition, retailers and suppliers can have conversations using the same language. This is an important contributor to transparency but also how issues are identified and resolved. Unless all supply chain stakeholders understand what is expected of them, it is difficult to calculate OTIF, particularly as retailers each have their own definitions that frequently change.

Beyond lacking a common definition of on-time, in-full, the McKinsey survey found that 79% of respondents said they preferred using a single metric to measure both in-time and in-full versus measuring each component separately. Additionally, 79% of respondents said they prefer to define “in-full” at the “case” rather than the “order” or “line” level, and 67% of respondents said they prefer to define “on-time” as the requested delivery date or the “must arrive by” date rather than the scheduled-delivery appointment date or the manufacturer’s committed-delivery date.

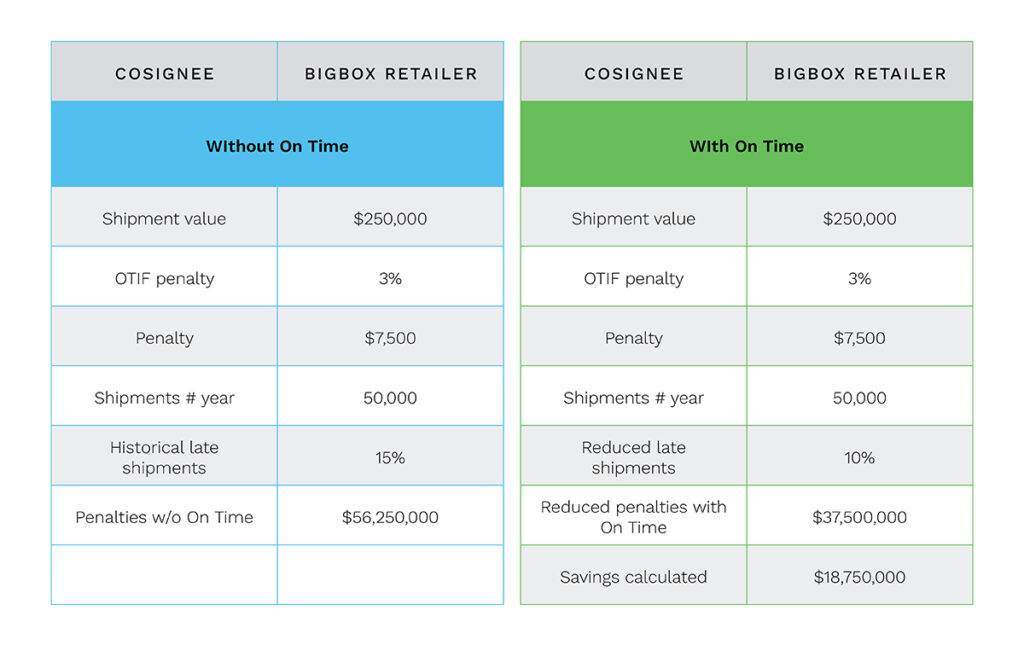

Figure 1: Reducing late shipments by 5% using Everstream’s “on time” solution created significant savings for this retail client.

It is easy to see why supply chain stakeholders would like to see a common OTIF calculation to simplify an already complex ecosystem.

OTIF requires real-time risk visibility

As shipping timelines continue to shorten to meet demand, suppliers are having to get smarter and more innovative in how they deliver. Much of their challenge is to get visibility into their risks early enough in the planning process to change course, if necessary, before OTIF commitments are threatened. Any one issue can instantly cause a chain reaction of delays that make meeting OTIF commitments all but impossible.

Weather is one of those inevitable and uncontrollable variables that regularly threaten shipments. The weather may be unpredictable to an extent, but with the right data consolidated and analyzed using actionable, predictive intelligence, most weather events can be predicted with remarkable accuracy. Same goes for infrastructure and social issues, which can be monitored and flagged as necessary. Using predictive risk management tools is key to creating an agile organization that can respond quickly and effectively. The earlier a company can identify a potential risk to OTIF delivery, the sooner they can make alternative plans before supply disruptions occur.

The beauty of this type of advanced technology is that some providers offer solutions that can be customized per customer, giving companies the ability to adapt their OTIF definitions to their customers’ requirements. OTIF calculations, therefore, can be made with greater confidence and less confusion.

The important elements of OTIF that suppliers, carriers, and shippers need to know as they judge overall risk are how likely they will be able to meet delivery windows and how well they can protect cargo.

Meeting delivery windows

The key to OTIF deliveries is visibility, but the benefit of having such insight is the ability to build confidence in ETAs and avoid making commitments that have a low chance of being met. ETAs should never be a guess or rough estimate. The customer defines expected time of arrival as a hard date they can plan on.

Decision-makers require predictive data to help them understand their risk as it relates to the company’s specified risk tolerance. To meet delivery windows, they need OTIF calculations that indicate the probability of each shipment delivering early, late, or within a customer’s requested delivery date.

Beyond the probability, it is important to identify the risks that could cause any delays, measured with an actual risk score. The risk score provides that common definition that so many survey respondents desire, customized to the risk tolerance agreed upon by leaders. With risk quantified for each shipment, it is much easier and faster to come to a decision about how to mitigate the highest-potential risks, and risk mitigation efforts can be executed days ahead of time.

Protecting cargo

Even when a shipment arrives within the required timeframe, if the cargo is damaged, the company will get dinged for failing to meet the in-full requirement. Advanced technology is now being used to break down each shipment at the granular level. For instance, each shipment is assessed based on the type of cargo being transported and its environmental tolerance, the predicted weather and temperatures along the route, and the planned mode of transportation for that specific cargo.

This type of analysis is excellent for companies to protect each shipment, as well as to reduce costs. Seasonal lane calendars are too general and inflexible to temperature extremes. With predictive analytics, logistics leaders managing temperature-sensitive cargo, such as food and beverages, pharmaceuticals, and more, can see when they have opportunities to use weather extremes to their advantage. They can potentially reduce overspend on temperature-controlled freight when temperatures drop and take additional measures to protect freight when temperatures rise.

Don’t ship in the dark

No matter where your company lies along the supply chain, access to real-time, reliable data is the only way to effectively estimate delivery times and stick to each customer’s OTIF requirements. Understanding all the variables and dependencies at this level helps companies become more agile to change, reduce costs, and have greater confidence in their decisions. The key to all this data is having it presented in a way that makes it immediately actionable and in hand well enough ahead of time to modify plans and expectations.

While not all risks are completely avoidable, having the best possible data as early as possible gives you a little wiggle room. Instead of being reactive and cleaning up the damage after it happens (and paying fines), you can be proactive and take action to avoid risk factors disrupting your supply chain altogether. OTIF is less of a burden and instead offers an opportunity to rise to the top.

Plus, predictive and prescriptive analytics also speed decisions. Today’s solutions are capable of alerting stakeholders of risks while also suggesting the best next action. The software analyzes all potential risks, options, and scenarios throughout the lifecycle of each shipment to determine which mitigation efforts have the greatest likelihood of success. For example, it may recommend a change in a shipment date, lane, or equipment type – days before pickup.

For companies that are serious about improving their competitive position and prioritize getting products to their destinations efficiently, reliably, and in the best condition, this type of advanced technology is a must. OTIF calculations may never be fully standardized, but with intelligent analytics, OTIF is attainable no matter how you define it.

Watch our webinar to learn how to save on cold chain monitoring.